Introduction: Starch granules in wheat endosperm are well-organized and reinforced by protein networks. However, mechanical forces during the milling process can partially or entirely damage these granules. As a result, flour produced contains a mixture of both intact and damaged starch granules. The damaged starch content in flour depends on milling system characteristics and roller settings. Specifically, milling with high speed and pressure can increase the proportion of damaged starch due to the fragile structure of the granules. This characteristic has a significant impact on the flour's water absorption and dough behavior, directly influencing baking performance. Additionally, damaged starch accelerates enzymatic reactions, altering the glycemic properties of the flour, an essential consideration in functional food production.

Methodology: At Bastak Instruments, a globally leading R&D center, five distinct bread wheat (Triticum aestivum L.) samples, termed as "Sample-01, Sample-02, Sample-03, Sample-04, and Sample-05," were milled using the Bastak 4500 double-pass laboratory mill with varied roller gap settings. Samples originated from different regions worldwide and were of local, medium-hard types. The wheat samples were milled using a total of five rolls (three break rolls and two reduction rolls), resulting in flours with varying levels of damaged starch. Flour yield was calculated as a percentage of the cleaned and tempered wheat initially milled.

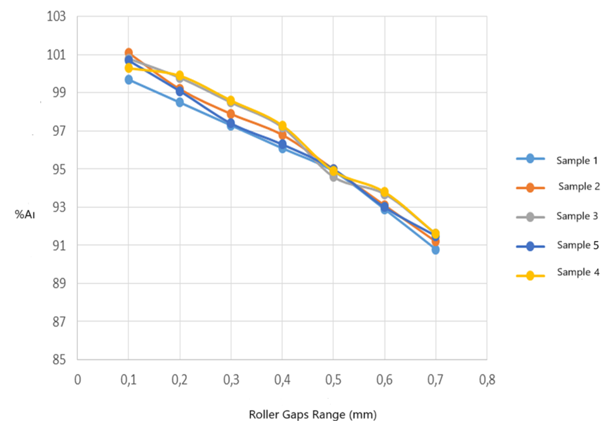

The damaged starch levels in the flours, obtained by milling with roller gaps ranging from 0.1 mm to 0.7 mm, were measured in six minutes using the Bastak SD Cheq 15000 device via the amperometric method under international standards.

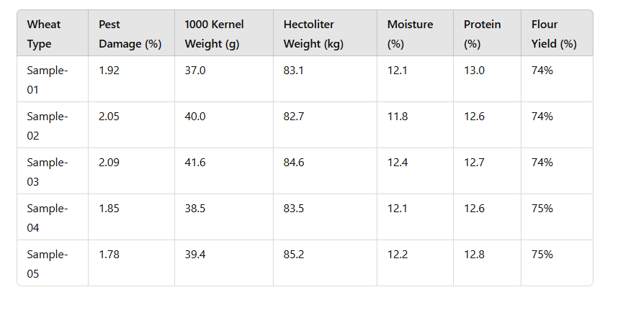

Physical and Chemical Characteristics: The wheat samples were analyzed using Bastak's Hectoliter 7000 device for hectoliter weight (kg), Bastak 16000 moisture meter with high-precision gold-plated sensors for moisture content (%), and the Bastak protein analysis device for protein content (%). The table below presents the average physical and chemical data of the five wheat samples, including yield percentages of the resulting flours obtained through different milling roller settings.

Table: Average Physical and Chemical Data of Five Different Wheat Samples and Flour Yields Obtained Through Milling with Various Roller Settings

Damaged starch levels in flours obtained through milling at different roller gaps (0.1 mm–0.7 mm) were measured using the Bastak SD Cheq 15000 starch damage analyzer in six minutes via the amperometric method, adhering to international standards.

Figure: Damaged Starch Levels Obtained by Milling Different Wheat Samples at Various Roller Gaps

To assess the baking quality of flour, dough analyses were conducted to examine the impact of damaged starch levels on dough quality. For optimal dough consistency and high-quality bread production, the amount of damaged starch in flour must remain balanced. Flours with excessive damaged starch have a high water absorption capacity, which increases the dough’s absorption, disrupting its homogeneity during kneading and reducing elasticity. These types of flours, which tend to absorb more water, cause excessive softening of the dough and prevent adequate gluten formation. Consequently, the dough’s gas-holding capacity diminishes, and due to the inability to retain gases produced during fermentation, the bread volume decreases, resulting in a denser crumb structure.

This imbalance negatively affects the outer crust formation throughout the baking process, compromising crust quality. Research suggests that using flours with optimal levels of damaged starch supports dough development and fermentation, enhancing bread volume and creating a porous, uniform crumb structure. However, when damaged starch levels exceed this optimum, gluten hydration becomes limited, making it difficult for gases to disperse effectively. As a result, due to the large surface area, the dough lacks sufficient gluten network formation, reducing gas retention capacity, diminishing bread volume, and leading to a denser crumb. For this reason, controlling damaged starch content within an optimal range is considered a critical parameter in bread production.

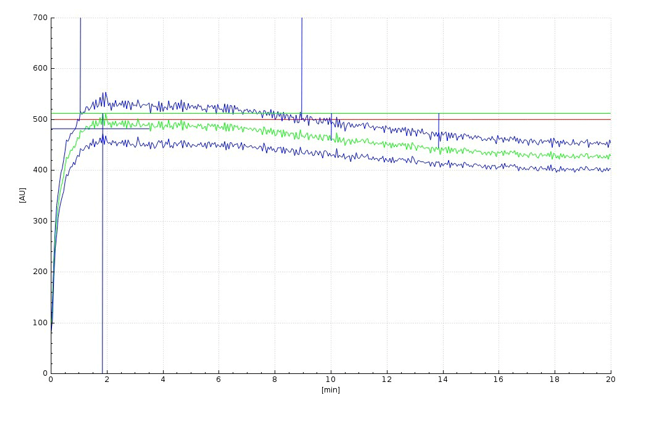

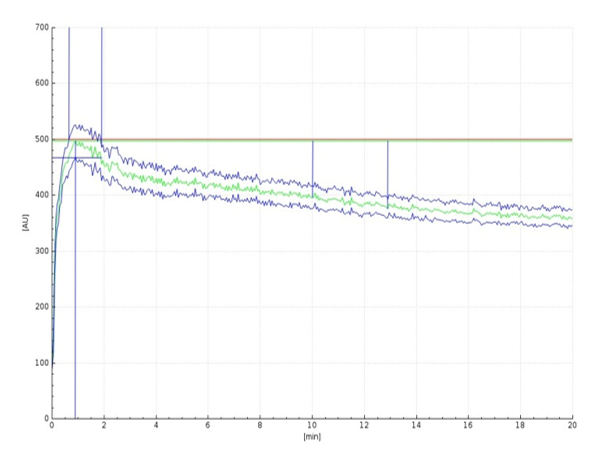

While intact starch granules can absorb approximately 0.33 times their weight in water, damaged starch granules can absorb their entire weight in water. Therefore, the amount of damaged starch significantly affects the baking quality of flour, analyzed using Bastak’s state-of-the-art Absograph 500 and Resistograph 500 dough rheology devices.

Dough analyses, including water absorption capacity/stability, were performed using flour samples containing varying levels of damaged starch, measured by the Bastak SD Cheq 15000 starch damage device. Using 300 g of flour samples, dough samples were prepared in the Absograph 500 device by subjecting them to mixing for 5 and 20 minutes. In addition, using the Bastak Resistograph 500 device, the dough’s rheological properties were assessed over sufficient test durations of 45, 90, and 135 minutes. The testing process utilized a special rail dough-stretching mechanism moving upward to eliminate gravitational effects, recording applied force for graphical analysis. The elasticity, resistance, and energy of the dough were determined according to international standards to achieve baked goods with ideal characteristics.

Figure : SAMPLE-01 (Roll gaps distance: 0.5 mm), Absograph Stability Graph

UCD: 23.5

Figure : SAMPLE-02 (Roll gaps distance: 0.2 mm), Absograph Stability Graph

UCD: 33,3

In dough samples prepared with flour containing high levels of damaged starch, it was observed that the excessive increase in damaged starch reduces gas retention capacity, as there is not enough gluten available to cover the increased surface area. This significantly impairs the fermentation process, deteriorates the internal structure of the bread, and ultimately affects overall bread quality.